| Three Pieces Forged Steel Ball Valve |

| Features |

- Three pieces body.

- Valve is designed in accordance with the requirements of API 6D for pipeline service.

- Anti-static and anti blow-out stem design.

- Seat design gives perfect tighness and is available as either self-relieving type or double piston effect type.

- Disign minimizes friction leading to low operating torque.

- Available as double block and bleed execution,which allows for venting and draining of ling fluid from the body cavity.

- Avaiable Full and Reduced bore.

- Ball valves firesafe tested according to BS EN 12266-2,API 6FA and API 607.

- Electric,pneumatic and hydravlic actuators are available on customer's requirement.

|

|

| Material specifications |

| No.. | Parts | Standard | Stainless Steel | Sour Service | Low Temperature Service | | 1 |

Body |

ASTM A105 |

ASTM A182 F316 |

ASTM A105 |

ASTM A350 LF2 |

| 2 |

Closure |

ASTM A105 |

ASTM A182 F316 |

ASTM A105 |

ASTM A350 LF2 |

| 3 |

Ball |

ASTM A105/ENP |

ASTM A182 F316 |

ASTM A105/ENP |

ASTM A105/ENP |

| 4 |

Seat Assembly |

Assembled |

Assembled |

Assembled |

Assembled |

| 5 |

Seat Insert |

25% Glass-filled PTFE |

25% Glass-filled PTFE |

25% Glass-filled PTFE |

25% Glass-filled PTFE |

| 6 |

Seat Ring |

ASTM A105/ENP |

ASTM A182 F316 |

ASTM A105/ENP |

A350 LF2/ENP |

| 7 |

Stem |

ASTM A182 F6a |

ASTM A182 F316 |

ASTM A182 F6a |

ASTM A182 F316 |

| 8 |

Trunnion Alignment Pin |

ASTM A182 F316 |

ASTM A182 F316 |

ASTM A182 F316 |

ASTM A182 F316 |

| 9 |

Shim |

ASTM A182 F316 |

ASTM A182 F316 |

ASTM A182 F316 |

ASTM A182 F316 |

| 10 |

Trunnion Support |

ASTM A105/ENP |

ASTM A182 F316 |

ASTM A105/ENP |

A350 LF2/ENP |

| 11 |

Gasket |

316SS+Graphite |

316SS+Graphite |

316SS+Graphite |

316SS+Graphite |

| 12 |

Gasket |

316SS+Graphite |

316SS+Graphite |

316SS+Graphite |

316SS+Graphite |

| 13 |

Gasket |

316SS+Graphite |

316SS+Graphite |

316SS+Graphite |

316SS+Graphite |

| 14 |

Spacer |

PTFE |

PTFE |

PTFE |

PTFE |

| 15 |

Firesage Gasket |

316SS+Graphite |

316SS+Graphite |

316SS+Graphite |

316SS+Graphite |

| 16 |

Gland cap |

ASTM A105 |

ASTM A182 F316 |

ASTM A105 |

ASTM A350 LF2 |

| 17 |

Top Flange |

ASTM A105 |

ASTM A182 F316 |

ASTM A105 |

ASTM A350 LF2 |

| 18 |

Thrust Washer |

316+PTFE+MoS2 |

316+PTFE+MoS2 |

316+PTFE+MoS2 |

316+PTFE+MoS2 |

| 19 |

Bearing |

316+PTFE+MoS2 |

316+PTFE+MoS2 |

316+PTFE+MoS2 |

316+PTFE+MoS2 |

| 20 |

Vent Valve |

Assembly |

Assembly |

Assembly |

Assembly |

| 21 |

Drain |

S.S. |

S.S. |

S.S. |

S.S. |

| 22 |

Seat Spring |

Inconel X-750 |

Inconel X-750 |

Inconel X-750 |

Inconel X-750 |

| 23 |

Grounding Spring |

S.S. |

S.S. |

S.S. |

S.S. |

| 24 |

Grounding Plunger |

ASTM A182 F316 |

ASTM A182 F316 |

ASTM A182 F316 |

ASTM A182 F316 |

| 25 |

O-Ring |

NBR |

NBR |

NBR |

NBR |

| 26 |

O-Ring |

NBR |

NBR |

NBR |

NBR |

| 27 |

O-Ring |

NBR |

NBR |

NBR |

NBR |

| 28 |

O-Ring |

NBR |

NBR |

NBR |

NBR |

| 29 |

Body Stud |

ASTM A193 B7 |

ASTM A193 B8 |

ASTM A193 B7M |

ASTM A320 L7M |

| 30 |

Body Nut |

ASTM A194 2H |

ASTM A194 8 |

ASTM A194 2HM |

ASTM A194 7M |

| 31 |

Screw |

C.S. |

C.S. |

C.S. |

ASTM A320 L7M |

| 32 |

Screw |

C.S. |

C.S. |

C.S. |

ASTM A320 L7M |

| 33 |

Gland Pin |

C.S. |

C.S. |

C.S. |

Carbon Steel |

| 34 |

Key |

C.S. |

C.S. |

C.S. |

ASTM 182 F304 |

| 35 |

Spring Pin |

C.S. |

C.S. |

C.S. |

C.S. |

| 36 |

Seat Iniection |

Assembly |

Assembly |

Assembly |

Assembly |

| 37 |

Stem Iniection |

Assembly |

Assembly |

Assembly |

Assembly |

|

|

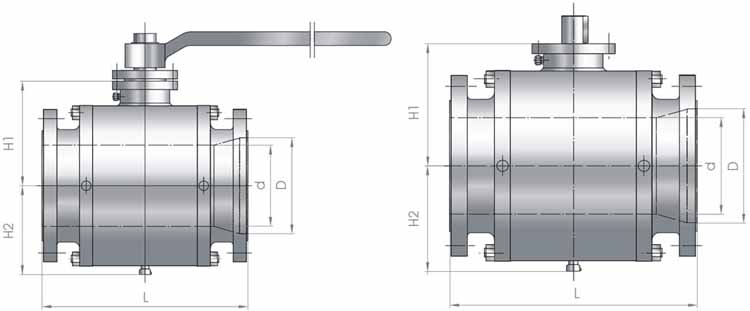

| Full Port (Class 300) | Reduce Port (Class 300) |

| Size(in) | D(mm) | L(mm) | H1(mm) | H2(mm) | Weight(Kg) | | 2 |

51 |

216 |

105 |

100 |

31 |

| 3 |

76 |

283 |

160 |

130 |

58 |

| 4 |

102 |

305 |

205 |

170 |

110 |

| 6 |

152 |

403 |

245 |

190 |

180 |

| 8 |

203 |

502 |

280 |

230 |

280 |

| 10 |

254 |

568 |

326 |

280 |

410 |

| 12 |

305 |

648 |

350 |

300 |

760 |

| 14 |

337 |

762 |

380 |

330 |

1100 |

| 16 |

387 |

838 |

415 |

350 |

1600 |

| 18 |

438 |

914 |

440 |

400 |

1700 |

| 20 |

489 |

991 |

500 |

440 |

2300 |

| 22 |

540 |

1092 |

520 |

470 |

2900 |

| 24 |

591 |

1143 |

585 |

530 |

3500 |

| 26 |

635 |

1245 |

630 |

570 |

4900 |

| 28 |

686 |

1346 |

645 |

650 |

6000 |

| 30 |

736 |

1397 |

700 |

700 |

6800 |

| 32 |

781 |

1524 |

740 |

750 |

8000 |

| 34 |

832 |

1626 |

770 |

780 |

9100 |

| 46 |

876 |

1727 |

820 |

800 |

11000 |

| 40 |

978 |

1956 |

900 |

900 |

14000 |

| 42 |

1022 |

2083 |

960 |

950 |

17000 |

| 48 |

1168 |

2170 |

1100 |

1100 |

25000 |

|

| Size(in) | d(mm) | D(mm) | L(mm) | H1(mm) | H2(mm) | Weight(Kg) | | 3×2×3 |

51 |

76 |

283 |

105 |

100 |

34 |

| 4×3×4 |

76 |

102 |

305 |

160 |

130 |

70 |

| 6×4×6 |

102 |

152 |

403 |

205 |

170 |

120 |

| 8×6×8 |

152 |

203 |

502 |

245 |

190 |

220 |

| 10×8×10 |

203 |

254 |

568 |

280 |

230 |

320 |

| 12×10×12 |

254 |

305 |

648 |

326 |

280 |

600 |

| 14×10×14 |

254 |

337 |

762 |

320 |

280 |

660 |

| 14×12×14 |

305 |

337 |

762 |

350 |

300 |

850 |

| 16×12×16 |

305 |

387 |

838 |

350 |

300 |

1000 |

| 16×14×16 |

337 |

387 |

838 |

380 |

330 |

1200 |

| 18×16×18 |

387 |

438 |

914 |

415 |

350 |

1700 |

| 20×16×20 |

387 |

489 |

991 |

415 |

350 |

1700 |

| 22×18×22 |

438 |

489 |

991 |

440 |

400 |

1850 |

| 24×20×24 |

489 |

591 |

1143 |

500 |

440 |

2700 |

| 30×24×30 |

591 |

736 |

1397 |

585 |

530 |

4600 |

| 36×30×36 |

736 |

876 |

1727 |

700 |

700 |

8000 |

| |

| Notes |

| 1.Face to face are according to API 6D |

| 2.For 2" to 24",flanges are accoring to ASME B16.5 |

| 3.For over 24",flanges are according to ASME B16.47 Series A. |

|

|

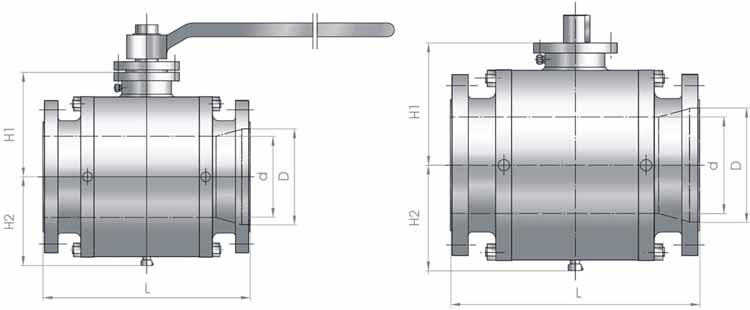

| Full Port (Class 600) | Reduce Port (Class 600) |

| Size(in) | D(mm) | L(mm) | H1(mm) | H2(mm) | Weight(Kg) | | 2 |

51 |

292 |

105 |

100 |

35 |

| 3 |

76 |

356 |

160 |

130 |

66 |

| 4 |

102 |

432 |

205 |

170 |

118 |

| 6 |

152 |

559 |

245 |

190 |

270 |

| 8 |

203 |

660 |

280 |

230 |

500 |

| 10 |

254 |

787 |

326 |

280 |

780 |

| 12 |

305 |

838 |

350 |

300 |

1100 |

| 14 |

337 |

889 |

380 |

330 |

1100 |

| 16 |

387 |

991 |

415 |

350 |

1600 |

| 18 |

438 |

1092 |

440 |

400 |

2100 |

| 20 |

489 |

1194 |

500 |

440 |

2700 |

| 22 |

540 |

1296 |

520 |

470 |

3900 |

| 24 |

591 |

1397 |

585 |

530 |

5000 |

| 26 |

635 |

1448 |

630 |

570 |

5700 |

| 28 |

686 |

1549 |

645 |

650 |

7000 |

| 30 |

736 |

1651 |

700 |

700 |

9000 |

| 32 |

781 |

1778 |

740 |

750 |

9800 |

| 34 |

832 |

1930 |

770 |

780 |

12000 |

| 46 |

876 |

2083 |

820 |

800 |

14000 |

| 40 |

978 |

2337 |

900 |

900 |

19000 |

| 42 |

1022 |

2437 |

960 |

950 |

22000 |

| 48 |

1168 |

2540 |

1100 |

1100 |

26000 |

|

| Size(in) | d(mm) | D(mm) | L(mm) | H1(mm) | H2(mm) | Weight(Kg) | | 3×2×3 |

51 |

76 |

356 |

105 |

100 |

42 |

| 4×3×4 |

76 |

102 |

432 |

160 |

130 |

90 |

| 6×4×6 |

102 |

152 |

559 |

205 |

170 |

160 |

| 8×6×8 |

152 |

203 |

660 |

245 |

190 |

300 |

| 10×8×10 |

203 |

254 |

787 |

280 |

230 |

560 |

| 12×10×12 |

254 |

305 |

838 |

326 |

280 |

820 |

| 14×10×14 |

254 |

337 |

889 |

320 |

280 |

920 |

| 14×12×14 |

305 |

337 |

889 |

350 |

300 |

1200 |

| 16×12×16 |

305 |

387 |

991 |

350 |

300 |

1400 |

| 16×14×16 |

337 |

387 |

991 |

380 |

330 |

1400 |

| 18×16×18 |

387 |

438 |

1092 |

415 |

350 |

1700 |

| 20×16×20 |

387 |

489 |

1194 |

415 |

350 |

2100 |

| 22×18×22 |

438 |

489 |

1194 |

440 |

400 |

2400 |

| 24×20×24 |

489 |

591 |

1397 |

500 |

440 |

3300 |

| 30×24×30 |

591 |

736 |

1651 |

585 |

530 |

5900 |

| 36×30×36 |

736 |

876 |

2083 |

700 |

700 |

11000 |

| |

| Notes |

| 1.Face to face are according to API 6D |

| 2.For 2" to 24",flanges are accoring to ASME B16.5 |

| 3.For over 24",flanges are according to ASME B16.47 Series A. |

|

|

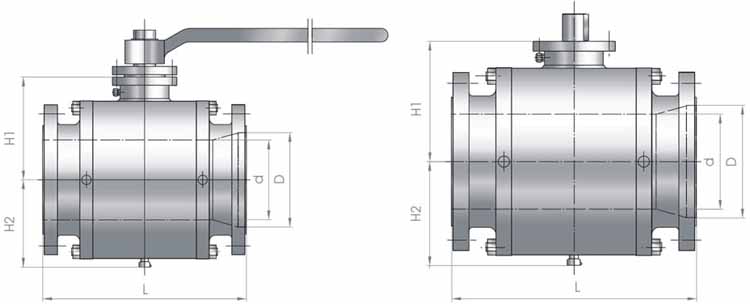

| Full Port (Class 900) | Reduce Port (Class 900) |

| Size(in) | D(mm) | L(mm) | H1(mm) | H2(mm) | Weight(Kg) | | 2 |

51 |

368 |

105 |

100 |

50 |

| 3 |

76 |

381 |

160 |

130 |

80 |

| 4 |

102 |

457 |

205 |

170 |

150 |

| 6 |

152 |

610 |

245 |

190 |

360 |

| 8 |

203 |

737 |

280 |

230 |

620 |

| 10 |

254 |

838 |

326 |

280 |

1100 |

| 12 |

305 |

965 |

350 |

300 |

1600 |

| 14 |

324 |

1029 |

380 |

330 |

1450 |

| 16 |

375 |

1130 |

415 |

350 |

2200 |

| 18 |

425 |

1219 |

440 |

400 |

2800 |

| 20 |

473 |

1321 |

500 |

440 |

4250 |

| 22 |

524 |

1422 |

520 |

470 |

6500 |

| 24 |

572 |

1549 |

585 |

530 |

7000 |

| 26 |

669 |

1651 |

630 |

570 |

8000 |

| 28 |

667 |

1753 |

645 |

650 |

9500 |

| 30 |

714 |

1880 |

700 |

700 |

12500 |

| 32 |

762 |

2032 |

740 |

750 |

12000 |

| 34 |

808 |

2159 |

770 |

780 |

18000 |

|

| Size(in) | d(mm) | D(mm) | L(mm) | H1(mm) | H2(mm) | Weight(Kg) | | 3×2×3 |

51 |

76 |

381 |

105 |

100 |

55 |

| 4×3×4 |

76 |

102 |

457 |

160 |

130 |

100 |

| 6×4×6 |

102 |

152 |

610 |

205 |

170 |

220 |

| 8×6×8 |

152 |

203 |

737 |

245 |

190 |

450 |

| 10×8×10 |

203 |

254 |

838 |

280 |

230 |

560 |

| 12×10×12 |

254 |

305 |

965 |

326 |

280 |

820 |

| 14×10×14 |

254 |

337 |

1029 |

320 |

280 |

920 |

| 14×12×14 |

305 |

337 |

1029 |

350 |

300 |

1200 |

| 16×12×16 |

305 |

387 |

1130 |

350 |

300 |

1400 |

| 16×14×16 |

324 |

387 |

1130 |

380 |

330 |

1400 |

| 18×16×18 |

375 |

438 |

1219 |

415 |

350 |

1700 |

| 20×16×20 |

375 |

489 |

1321 |

415 |

350 |

2100 |

| 22×18×22 |

425 |

489 |

1321 |

440 |

400 |

2400 |

| 24×20×24 |

473 |

591 |

1549 |

500 |

440 |

3300 |

| 30×24×30 |

572 |

736 |

1800 |

585 |

530 |

5900 |

| 36×30×36 |

714 |

876 |

2286 |

700 |

700 |

11000 |

| |

|

| Notes |

1.Face to face are according to API 6D

2.For 2" to 24",flanges are accoring to ASME B16.5

3.For over 24",flanges are according to ASME B16.47 Series A. |

|

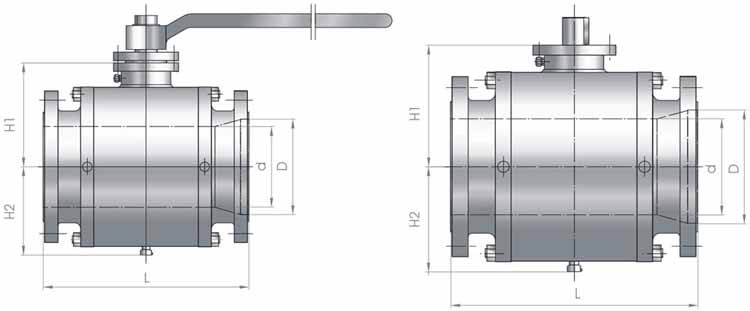

| Full Port (Class 1500) | Reduce Port (Class 1500) |

| Size(in) | D(mm) | L(mm) | H1(mm) | H2(mm) | Weight(Kg) | | 2 |

51 |

368 |

110 |

105 |

60 |

| 3 |

76 |

470 |

165 |

130 |

100 |

| 4 |

102 |

546 |

220 |

170 |

210 |

| 6 |

146 |

705 |

260 |

230 |

500 |

| 8 |

194 |

832 |

310 |

290 |

850 |

| 10 |

241 |

991 |

370 |

360 |

1600 |

| 12 |

289 |

1130 |

430 |

440 |

2300 |

| 14 |

317 |

1257 |

450 |

450 |

2950 |

| 16 |

362 |

1384 |

500 |

600 |

4200 |

| |

|

| Size(in) | d(mm) | D(mm) | L(mm) | H1(mm) | H2(mm) | Weight(Kg) | | 3×2×3 |

51 |

76 |

470 |

110 |

105 |

70 |

| 4×3×4 |

76 |

102 |

546 |

165 |

130 |

130 |

| 6×4×6 |

102 |

146 |

705 |

220 |

170 |

300 |

| 8×6×8 |

146 |

194 |

832 |

260 |

230 |

580 |

| 10×8×10 |

194 |

241 |

991 |

310 |

290 |

1100 |

| 12×10×12 |

241 |

289 |

1130 |

370 |

360 |

1800 |

| 14×10×14 |

241 |

317 |

1257 |

370 |

360 |

2200 |

| 14×12×14 |

289 |

317 |

1257 |

430 |

440 |

2600 |

| 16×12×16 |

289 |

362 |

1384 |

430 |

440 |

2900 |

| 16×14×16 |

317 |

362 |

1384 |

450 |

450 |

3300 |

| 18×16×18 |

362 |

407 |

1537 |

500 |

600 |

5000 |

| 20×16×20 |

362 |

457 |

1664 |

500 |

600 |

6000 |

|

| Full Port (Class 2500) | Reduce Port (Class 2500) |

| Size(in) | D(mm) | L(mm) | H1(mm) | H2(mm) | Weight(Kg) | | 2 |

44.5 |

415 |

120 |

130 |

100 |

| 3 |

63.5 |

578 |

180 |

200 |

200 |

| 4 |

89 |

673 |

230 |

250 |

390 |

| 6 |

133 |

914 |

260 |

250 |

790 |

| 8 |

181 |

1022 |

400 |

350 |

1400 |

| 10 |

226 |

1270 |

450 |

420 |

2200 |

| 12 |

267 |

1422 |

520 |

510 |

3400 |

|

| Size(in) | d(mm) | D(mm) | L(mm) | H1(mm) | H2(mm) | Weight(Kg) | | 3×2×3 |

44.5 |

63.5 |

578 |

120 |

130 |

170 |

| 4×3×4 |

63.5 |

89 |

673 |

180 |

200 |

280 |

| 6×4×6 |

89 |

133 |

914 |

260 |

250 |

520 |

| 8×6×8 |

133 |

181 |

1022 |

400 |

250 |

1100 |

| 10×8×10 |

181 |

226 |

1270 |

450 |

350 |

1700 |

| 12×10×12 |

226 |

267 |

1422 |

450 |

420 |

2600 |

|

| Notes | |

1.Face to face are according to API 6D

2.For 2" to 24",flanges are accoring to ASME B16.5

3.For over 24",flanges are according to ASME B16.47 Series A. |